The working principle of a three-way catalytic converter is that when high-temperature exhaust gas passes through the converter, the purifier in the CFC enhances the activity of CO, HC, and NOx, prompting them to undergo a specific oxidation-reduction chemical reaction. At high temperatures, CO is oxidized to colorless, non-toxic carbon dioxide; HC compounds are oxidized to water (H₂O) and carbon dioxide; and NOx is reduced to nitrogen and oxygen. These three harmful gases are converted to harmless gases, effectively purifying the exhaust.

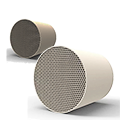

The CFC is similar to a muffler. Its outer surface is made of a double layer of stainless steel sheets in a cylindrical shape. Asbestos fiber felt, a thermal insulation material, is placed between the two thin layers. Inside, a purifier is placed between mesh partitions. The purifier consists of a carrier and a catalyst. The carrier is typically made of aluminum oxide and can be spherical, polygonal, or with mesh partitions. The purifier actually acts as a catalyst, also known as a catalyst. Catalysts are made of platinum, rhodium, or palladium. Spraying one of these metals onto the carrier creates the purifier.

Three-way catalytic converters generally do not require cleaning. If they exhibit severe oxidation, they are simply replaced. Because the operating temperature of a three-way catalytic converter is around 350°C, it is best to avoid any residual liquid water, making cleaning difficult.

In the automotive industry, three-way catalytic converters are important exhaust gas purification devices. The use of their carrier materials not only affects the vehicle's environmental performance but also has a significant impact on investment opportunities.

Three-way catalytic converter carrier materials primarily include ceramic and metal. Ceramic carriers offer lower cost, better thermal stability, and a higher specific surface area, providing more attachment sites for the catalyst, thereby improving catalytic efficiency. Metal carriers offer better thermal conductivity and mechanical strength and are widely used in high-performance vehicles and special operating conditions.

From an investment perspective, with increasingly stringent environmental regulations, demand for three-way catalytic converters in the automotive industry continues to grow, directly driving the development of the carrier material market. Investment in ceramic carrier materials, while relatively mature technology and fierce market competition are key, is fueled by large-scale demand, ensuring a certain degree of investment stability. Metal carrier materials, on the other hand, offer significant market potential due to their advantages in high-end vehicles and special applications, but they also present higher technical barriers and investment risks.