What is VOC

Volatile organic compounds (VOCs) are compounds with a boiling point between 50°C and 250°C at a pressure of 101.32 kPa. They exist as gases at room temperature. Based on their chemical structure, they can be further divided into eight categories: alkanes, aromatic hydrocarbons, alkenes, halogenated hydrocarbons, esters, aldehydes, ketones, and others. The main components of VOCs are hydrocarbons, halogenated hydrocarbons, oxygenated hydrocarbons, and nitrogenated hydrocarbons. They include benzene series, organic chlorides, freon series, organic ketones, amines, alcohols, ethers, esters, acids, and petroleum hydrocarbon compounds.

Outdoors, VOCs primarily come from industrial waste gases from fuel combustion and transportation, automobile exhaust, and photochemical pollution.

Indoors, VOCs primarily come from combustion products such as coal and natural gas, smoke from smoking, heating, and cooking, building and decorative materials, furniture, household appliances, cleaning agents, and human emissions. During interior decoration and renovation projects, VOCs primarily come from paints, coatings, and adhesives. Typical VOC levels in paint range from 30 to 70 grams per liter. Due to their high volatility, 90% of VOCs can evaporate within 10 hours of paint application.

Applications:

Industrial Waste Gas Treatment

• Treats pollutants such as VOCs (volatile organic compounds), NOₓ, and CO generated in industry.

• Exhaust gas purification systems for the chemical, spray coating, pharmaceutical, and electronics industries

Treatment:

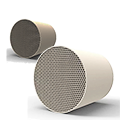

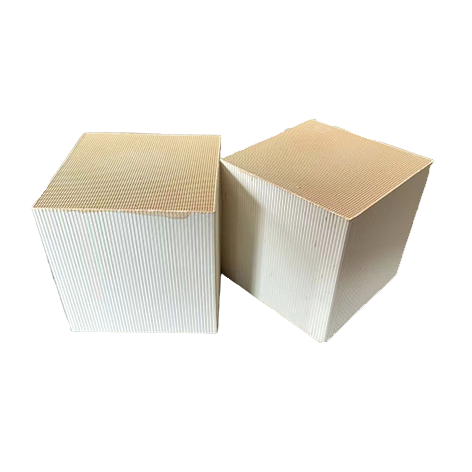

Catalytic oxidation. Currently, two types of catalysts are used in catalytic oxidation: precious metal catalysts and non-precious metal catalysts. Precious metal catalysts mainly include Pt, Pd, etc., which are attached to the catalyst carrier in the form of fine particles, and the catalyst carrier is usually a metal or ceramic honeycomb, or bulk filler; non-precious metal catalysts are mainly made of transition metal oxides, such as MnO2, mixed with a binder in a certain proportion and then made into a catalyst. In order to effectively prevent the catalyst from losing its catalytic activity after poisoning, substances that can poison the catalyst, such as Pb, Zn and Hg, must be thoroughly removed before treatment. If the catalyst poisons and covering substances in the organic waste gas cannot be removed, this catalytic oxidation method cannot be used to treat VOCs