Classification of Common Precious Metal Catalysts:

1.1 Heterogeneous Catalysis

Heterogeneous catalysis accounts for four-fifths of all catalytic reactions. Most heterogeneous catalysts are insoluble solids, and most are carrier-supported precious metals, such as Pt-Rh/Al2O3 and Pt-Pd/Al2O3.

1.2 Homogeneous Catalysis

These are typically soluble compounds (salts or complexes), such as palladium chloride, rhodium chloride, and triphenylphosphine carbonyl rhodium.

1.3 Others

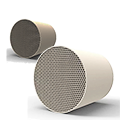

Based on the shape of the carrier, supported catalysts can be categorized as spherical, microparticle, honeycomb, and columnar. Catalysts can also be classified based on the primary active metal in the catalyst. Commonly used catalysts include platinum, palladium, and silver.