Metal catalysts are an important type of industrial catalyst. They primarily include bulk catalysts, such as electrolytic silver catalysts, molten iron catalysts, and platinum mesh catalysts; dispersed or supported metal catalysts, such as Pt-Re/-Al2O3 reforming catalysts and Ni/Al2O3 hydrogenation catalysts.

Classification of Common Precious Metal Catalysts:

1.1 Heterogeneous Catalysis

Heterogeneous catalysis accounts for four-fifths of all catalytic reactions. Most heterogeneous catalysts are insoluble solids, and most are carrier-supported precious metals, such as Pt-Rh/Al2O3 and Pt-Pd/Al2O3.

1.2 Homogeneous Catalysis

These are typically soluble compounds (salts or complexes), such as palladium chloride, rhodium chloride, and triphenylphosphine carbonyl rhodium.

1.3 Others

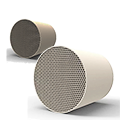

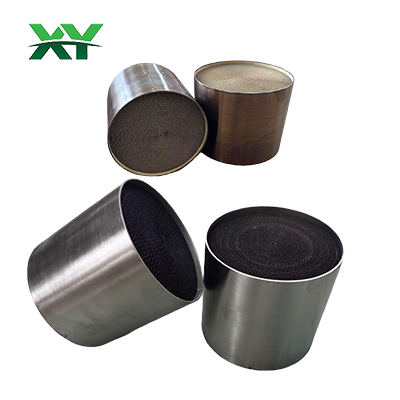

Based on the shape of the carrier, supported catalysts can be categorized as spherical, microparticle, honeycomb, and columnar. Catalysts can also be classified based on the primary active metal in the catalyst. Commonly used catalysts include platinum, palladium, and silver.

Mechanism of Metal Catalysts

1. Adsorption of Metal Catalysts

Adsorption is a crucial step in heterogeneous catalysis. Transition metals can adsorb gases such as oxygen. Their strong chemical adsorption capacity is related to the properties of transition metals. This is because they possess vacant d orbitals or unpaired d electrons in their outermost electron shells, making them prone to forming chemical bonds with gas molecules. Their low activation energy allows them to adsorb most gases. Most importantly, their d orbitals are either half-filled or fully filled, making them relatively stable and less likely to form chemical bonds with gas molecules.

In a catalytic reaction, a metal catalyst first adsorbs one or more reactant molecules, enabling them to react chemically on the metal surface. The activity of a metal catalyst for a particular reaction is related to the relative stability of the intermediates formed after the reactants adsorb on the catalyst surface.